Exactly How Smart Foundry Innovation Is Reinventing Light Weight Aluminum Spreading Workflows

Smart factory technology is significantly transforming light weight aluminum spreading process. With the assimilation of automation, IoT connectivity, and information analytics, procedures are coming to be a lot more precise and effective. This shift minimizes problems and waste while boosting safety and security and performance. As the industry adapts to these advancements, new obstacles and chances emerge. Comprehending the full effect of these improvements is crucial for stakeholders intending to stay competitive in a rapidly advancing landscape.

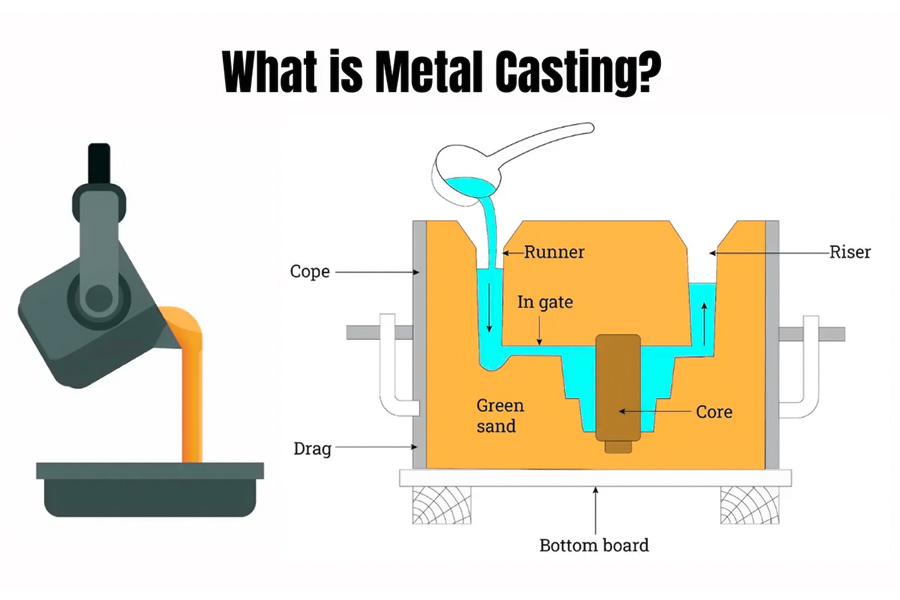

The Function of Automation in Aluminum Casting

As the need for effectiveness and accuracy in manufacturing boosts, automation plays an essential role in aluminum casting processes. Automated systems simplify procedures, minimize the possibility for human mistake, and enhance total productivity. By integrating robotics for tasks such as mold and mildew handling and product putting, foundries have the ability to attain consistent top quality and faster turnaround times. Automation likewise assists in real-time surveillance of the spreading process, allowing instant modifications and decreasing problems.

Progressed control systems manage temperature level, alloy, and stress structure with high precision, making sure the honesty of the last product. These modern technologies not only maximize source usage however also add to a much safer job atmosphere by reducing the demand for manual intervention in dangerous conditions. Overall, the application of automation in light weight aluminum spreading significantly improves operational efficiency, leading the way for improvements in the industry and establishing new requirements in production abilities.

Enhancing Performance With Iot Connectivity

IoT connectivity changes light weight aluminum spreading by allowing seamless communication between makers and systems. This connectivity enables real-time monitoring and control of numerous procedures, substantially improving functional effectiveness. By incorporating IoT tools, factories can automate information collection from equipment and sensing units, assisting in prompt responses and changes.

The capacity to remotely access machine efficiency metrics cultivates proactive maintenance, minimizing downtime and lessening costly disturbances. Furthermore, IoT connectivity simplifies supply chain administration by offering precise inventory tracking and promoting prompt purchase of materials.

Employees benefit from improved safety and security and functional designs, as IoT systems can flag possible dangers and optimize workflows. Eventually, the combination of IoT in aluminum spreading not only improves performance but likewise adds to a smarter, much more responsive production setting, positioning shops to satisfy growing market demands efficiently. This technical innovation establishes a structure for future innovations within the sector.

The Power of Data Analytics in Casting Procedures

Information analytics plays a vital role in enhancing light weight aluminum casting processes through real-time procedure tracking and predictive upkeep insights. By harnessing information, foundries can identify inefficiencies and prepare for tools failings before they occur. This proactive method not just boosts efficiency but also minimizes operational prices in the casting industry.

Real-time Process Monitoring

Real-time procedure tracking has actually become a critical part in aluminum spreading, leveraging advanced data analytics to improve manufacturing effectiveness and quality. This innovation allows manufacturers to collect and examine data throughout the casting process, permitting immediate insights into functional efficiency. By constantly tracking variables such as material, temperature, and stress circulation, factories can recognize discrepancies from perfect conditions instantly. This not just helps with timely changes yet also minimizes the likelihood of issues and waste. In addition, real-time monitoring cultivates a data-driven society, encouraging operators to make educated decisions on the store floor. Consequently, aluminum casting procedures can attain higher consistency and integrity, ultimately causing improved item top quality and client fulfillment.

Anticipating Maintenance Insights

The assimilation of innovative analytics not only boosts real-time procedure surveillance but also plays a substantial function in anticipating maintenance within light weight aluminum spreading procedures. By leveraging data accumulated from equipment, operators can identify patterns and anomalies that precede tools failures. This proactive approach permits timely treatments, decreasing downtime and upkeep expenses. Advanced formulas assess historical efficiency information to anticipate potential malfunctions, making it possible for shops to set up maintenance activities throughout non-productive hours. Because of this, operational effectiveness improves, and the life-span of essential tools is extended. Additionally, anticipating maintenance understandings encourage shops to assign resources better, making sure that proficient employees are offered when required most. Generally, data-driven techniques are transforming upkeep practices in the light weight aluminum spreading industry.

Streamlining Production Operations

Optimizing manufacturing workflows is essential for boosting efficiency in light weight aluminum spreading operations. Smart factory innovation helps with the automation of numerous phases in the spreading procedure, enabling a more structured method. By incorporating innovative software application and real-time data analytics, producers can keep track of production metrics and identify traffic jams immediately. This enables an aggressive action to possible problems, minimizing downtime and enhancing throughput.

Moreover, the implementation of robotic systems in product handling and mold preparation minimizes manual work and improves precision. This automation not just speeds up production however also assures uniformity in high quality. Furthermore, improved organizing tools permit for far better source allotment, guaranteeing that devices and employees are made use of efficiently. On the whole, the integration of wise innovation into aluminum casting workflows causes substantial enhancements in functional performance, leading to faster turn-around times and boosted competition on the market.

Decreasing Waste and Environmental Influence

Applying wise factory technology significantly contributes to reducing waste and minimizing environmental impact in aluminum spreading. By integrating sophisticated information analytics and artificial intelligence, foundries can maximize product usage, making certain that light weight aluminum is made use of much more successfully throughout the spreading process. Metal Foundry. This precision results in a considerable reduction in scrap prices, as manufacturers can read more better anticipate and manage the problems under which light weight aluminum is put and strengthened

Wise innovation facilitates real-time tracking of power consumption and exhausts, enabling shops to identify locations for renovation. With automated systems, energy use can be minimized, straight reducing the carbon footprint related to light weight aluminum production. Additionally, the innovation promotes recycling practices by effectively reprocessing and segregating scrap light weight aluminum, further decreasing the demand for basic material extraction. In general, the fostering of clever factory technology not only improves functional effectiveness but additionally fosters an extra sustainable strategy to light weight aluminum spreading.

Adjusting to Market Needs With Smart Technology

As market demands evolve swiftly, factories that take advantage of wise modern technology can swiftly adjust to altering customer demands in aluminum spreading. By incorporating advanced data analytics, artificial intelligence, and IoT gadgets, these facilities gain real-time understandings into manufacturing processes and customer choices. This capacity allows them to adjust production routines, optimize resource allowance, and improve item layouts with better agility.

Smart innovations help with an even more receptive supply chain, enabling foundries to anticipate trends and react proactively to variations sought after. Automation also plays a substantial function, lowering preparations and increasing the capacity to tailor orders without endangering high quality. Furthermore, boosted interaction between systems warranties that shops stay aligned with market changes, allowing them to supply cutting-edge services that fulfill particular customer requirements. Adjusting to these dynamics not only enhances competitiveness however likewise promotes long-term relationships with consumers that value flexibility and responsiveness in their published here light weight aluminum casting partners

Future Trends in Smart Foundry Solutions

The future of clever shop remedies is poised to be formed considerably by developments in automation within casting processes. As automation technologies come to be much more integrated, they will assist in extra efficient production process and reduce human mistake. In addition, data-driven decision making will empower factories to optimize procedures and improve item high quality with real-time analytics.

Automation in Casting Processes

Transforming the light weight aluminum spreading market, automation innovations are poised to reshape casting procedures considerably. Automated systems streamline procedures by decreasing hands-on labor and boosting precision throughout the spreading process. Using robot arms for mold and mildew handling and pouring minimizes the risk of human mistake, enhancing security and consistency in production. Furthermore, progressed artificial intelligence formulas enhance the spreading specifications, enabling real-time adjustments based on environmental problems and product properties. This not only enhances effectiveness yet also decreases waste, lining up with sustainable production techniques (Aluminum Casting). As automation remains to develop, the combination of clever sensors and IoT tools assures better improvements, enabling factories to attain greater levels of efficiency and high quality in aluminum casting operations

Data-Driven Decision Making

Data-driven decision making is becoming an important part in the evolution of wise factory remedies, particularly within the aluminum spreading market. By leveraging real-time information analytics, factories can enhance their procedures, lower waste, and improve product high quality. Advanced maker learning algorithms evaluate large datasets to identify patterns and anomalies, making it possible for suppliers to make enlightened selections about products, production schedules, and tools upkeep. This proactive approach not just enhances operational performance but likewise promotes technology in product development. As the sector progressively adopts these technologies, the capacity to harness information will distinguish leading factories from their rivals. Inevitably, data-driven decision production is positioned to change light weight aluminum spreading, driving lasting growth and operational excellence in the years in advance.

Often Asked Questions

What Are the Initial Costs of Executing Smart Shop Modern Technology?

Preliminary expenses of implementing clever factory modern technology can vary considerably, ranging from equipment acquisitions and software application integration to training costs. Companies commonly encounter significant investments, but potential long-lasting savings might justify these upfront expenditures.

Just How Does Smart Foundry Innovation Impact Workforce Training Needs?

Smart foundry technology requires enhanced workforce training to furnish staff members with abilities in innovative automation, information evaluation, and equipment procedure. This change promotes continual learning, guaranteeing workers adapt to progressing processes and preserve operational effectiveness.

Can Small Foundries Take Advantage Of Smart Modern Technology Solutions?

What Are the Cybersecurity Dangers Associated With Iot in Foundries?

Cybersecurity risks connected with IoT in foundries include possible top article information breaches, unauthorized access, and operational disruptions. Vulnerabilities in connected gadgets can result in substantial financial losses and compromise sensitive information, demanding robust security procedures.

How much time Does It Take to See ROI From Smart Foundry Investments?

Generally, companies observe a roi from clever factory innovation within one to three years. Aspects influencing this timeline include preliminary financial investment dimension, execution performance, and enhancements in functional efficiency and expense savings.